| Range |

As we control all types of high tech systems, Our work is way more than only repairing. We offer you a complete update of your industrial electronic systems and so, a durable work of all your equipment, of all brands

| Super Vision | Drives | Boards | ||

| Terminals, Monitors, display units | Synchronous, Asynchronous, Brushless, step by Step | Analogical, Digital, Specific systems | ||

| Robots | PLC | Digital Controls | ||

| Power supplies, Input/Output, CPU, Axis Controls, Power, Display Units, Security bords | Power supplies, Input/Output, CPU, Couplers, Communications, Operator pannels/Supervisions/ Panel view |

Screens, CPU, Keybords, Axis Controls, Display Units, Power Supplies, PLC, Power |

| Our Repair Offer |

|

FREE QUOTATION Fixed price quotation within 48 hours from date of reception in our repair shop. Repair and Delivery time Between 2 and 4 weeks after placed order. Emergencies All urgent repairs will be considered with a special and high-priority assistance, which justifies an increase of the price. |

|||

|

Our offer includes

Cleaning of the system Failure research System analysis Preventive replacement of some components Curative replacement of the defective components, which can be supplied Adjustments (according to the documentation we have) Tests (according to the technical tools: static, dynamic, functional) Detailed repair report Packaging of high quality Transport fees 6 months guarantee |

|||

| Different Means |

|

|

|

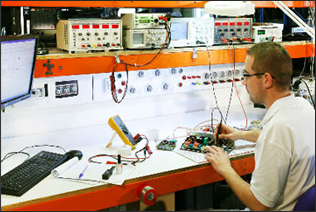

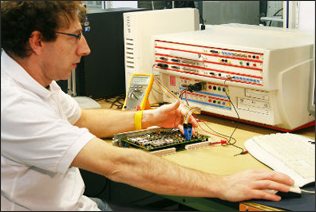

Meictech Electronic is composed of around one hundred of workers divided into several services, which enables us to answer to all your needs. Our 70 technicians and engineers have a huge knowledge of repairs in industrial electronic of medium and high technology. Meictech has established a database about all characteristics of electronic components thanks to experience acquired day after day since the creation of the company (25 years). Our teams, our repair shops and our know-how enables us to always keep the satisfaction of our customers at the heart of our projects. Cleaning means of your systems, static and dynamic means of analysis for all components, means of test and means of logistics enables us to garantee 95 % of success on your electronic repairs. |

||

| A Cleaning | |||

| According to the state of dirtyness of the material and save the technical obligations, each material is cleaned after having received your order. | |||

| Cleaning system by projection in closed-circuit | |||

|

|

||

| B Analysis | |||

| Our challenge of everyday is of course your satisfaction. That is why we invest in means every year to enable us to understand and better repair a more and more complex technology. Thanks to these devices, we can make static and dynamic tests of digital and analogical components (both obsolete and the ones of the new generation) |

|||

|

|

||

| C Test | |||

| In order to make all our repairs reliable, we have developed many test benches from manufacturers in the more spread brands of industry, as well for automatism, digital controls, speed variation as for robotics. | |||

|

|

||

| Test Benches for PLC | Test Benches for Digital Control | ||

| C Logistics | |||

| Our three repair shops are linked to a specific application of our IT system, it enables: | |||

|

|

||